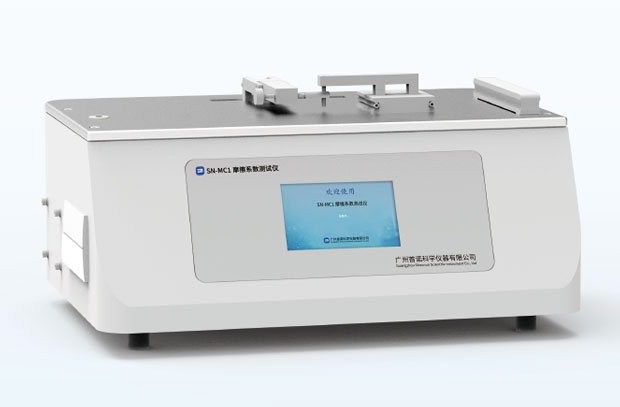

In the production and application of flexible packaging materials, the Friction Coefficient Tester plays a pivotal role. It directly impacts packaging production efficiency and influences the storage, transportation, and end-user experience of the final product. So, at which specific stage in the packaging material testing process does the friction coefficient tester come into play? And which industries rely on it? This article, based on practical application scenarios, provides a clear breakdown.

Specific Applications of the Friction Coefficient Tester in the Testing Workflow

Friction coefficient testing is not a one-time task but an ongoing monitoring activity throughout multiple critical stages of quality control, from raw materials to finished packaging products.

1. Incoming Raw Material Inspection

This is the first checkpoint for quality control. Incoming base materials such as films, metallized films, and papers must be sampled and tested using a Film Friction Coefficient Tester. If the friction coefficient of raw materials is too high, it may cause issues like unwinding problems or misregistration in subsequent printing and bag-making processes. If it is too low, it may lead to material slippage during stacking, affecting conveying stability. Testing at this stage helps eliminate production risks stemming from inappropriate material slip properties at the source.

2. In-Process Production Control

This is where the friction coefficient tester is used most frequently. Especially after processes like printing, laminating, coating, and curing, the surface characteristics of materials can change significantly. For example:

-

After Printing: The application of ink alters the smoothness of the film surface, requiring testing of the ink layer's impact on the friction coefficient.

-

After Laminating: The type and application amount of adhesive significantly affect the frictional properties of the composite film, impacting the smoothness of downstream slitting and bag-making processes.

-

After Curing: For some materials, slip agents may migrate or undergo crystalline changes during curing, causing the friction coefficient to change over time, necessitating follow-up testing.

In this stage, the Static and Dynamic Friction Coefficient Tester is particularly crucial. It measures both the force required to initiate movement (static friction coefficient) and the force needed to maintain movement (dynamic friction coefficient), providing precise data to adjust production parameters like tension, temperature, and speed.

3. Final Inspection of Finished Products

Before packaging bags or rolls leave the factory, final testing must be conducted according to national standards (e.g., GB 10006, ISO 8295) or customer agreements. The friction coefficient data at this point is a vital part of the product compliance certificate, ensuring the material meets the requirements of downstream customers' high-speed automatic filling and packaging lines, thereby preventing production line stoppages due to friction-related issues.

Which Industries Heavily Rely on Friction Coefficient Testing?

The application of friction coefficient testers extends far beyond traditional packaging. Any industry concerned with the surface slip properties of materials finds this instrument essential.

1. Food and Beverage Packaging Industry

This is the largest application sector. Whether it's ensuring low friction coefficient for snack bags to facilitate smooth filling or achieving an optimal friction coefficient for yogurt lid films to balance easy-open features with stack stability, precise control of the friction coefficient is indispensable. High-speed vertical form-fill-seal machines have particularly stringent requirements for roll film friction coefficients.

2. Pharmaceutical and Medical Device Packaging Industry

The friction coefficient of packaging materials like pharmaceutical blister packs (aluminum foil, PVC sheets) and sterile medical device composite pouches directly affects the efficiency and success rate of automated packaging lines. Moreover, excessively high friction coefficients can generate particles, compromising drug safety, making testing requirements exceptionally strict.

3. Daily Chemical and Consumer Electronics Packaging Industry

The opening performance, tactile feel, and sliding behavior in vending machines for products like shampoo stand-up pouches, toothpaste tubes, and smartphone screen protectors are all closely related to the friction coefficient of their packaging materials.

4. Logistics and Warehousing Industry

In recent years, friction coefficient testing has extended into unit load logistics. For instance, the bundling force and anti-slip properties of stretch wrap and pallet wrap, as well as the anti-slip performance of stacked cartons, require evaluation through scientific Friction Coefficient Test Methods to prevent cargo collapse during transportation.

How to Choose and Implement Effective Friction Coefficient Testing?

Selecting the correct instrument and test method is prerequisite for obtaining reliable data. Current mainstream Friction Coefficient Test Methods mostly follow the sled principle, measuring the resistance when two contact surfaces move relative to each other under constant speed and pressure. Key considerations during implementation include:

-

Standardized Environment: Temperature and humidity significantly affect the friction coefficient. Tests should be conducted in a standard environment (e.g., 23±2°C, 50±10% RH).

-

Sample Representativeness: Samples should cover both the transverse and longitudinal directions of the material, considering different test surface combinations (e.g., film-to-film, film-to-metal).

-

Data Interpretation and Application: A single friction coefficient value has limited meaning. It must be analyzed in conjunction with specific application scenarios (e.g., type of packaging machine, speed) to establish an internal corporate database of material performance standards.

Conclusion

In summary, the Friction Coefficient Tester is a vital bridge connecting the physical properties of packaging materials to their actual performance on production lines. It is integral to quality monitoring across the entire chain—from raw materials to in-process goods and finished products—and is widely used in numerous industries sensitive to packaging performance, such as food, pharmaceuticals, daily chemicals, and logistics. By scientifically utilizing the Static and Dynamic Friction Coefficient Tester and implementing standardized Friction Coefficient Test Methods, companies can effectively enhance production efficiency, reduce waste, ensure final packaging quality, and gain a competitive edge in the market. Choosing a reliable and standards-compliant Film Friction Coefficient Tester is fundamental to ensuring the effective operation of this quality control system.