In the pharmaceutical industry, drug safety and efficacy are the lifeline. This depends not only on the composition and manufacturing process of the drug itself but also on the quality of its external "protective layer"—the pharmaceutical packaging material. Packaging materials come into direct contact with drugs, and their barrier properties, seal integrity, physical strength, and chemical stability directly impact the safety and effectiveness of the drug during storage, transportation, and even use. Therefore, a scientific, rigorous, and regulation-compliant testing system is an indispensable part of pharmaceutical quality control.

Addressing this core need, we specialize in providing comprehensive and professional testing instrument solutions for pharmaceutical packaging materials to the pharmaceutical manufacturing and quality inspection sectors. Our instrument development closely aligns with domestic and international pharmacopoeias and relevant industry standards, aiming to help companies establish a complete quality verification闭环 from materials to finished products.

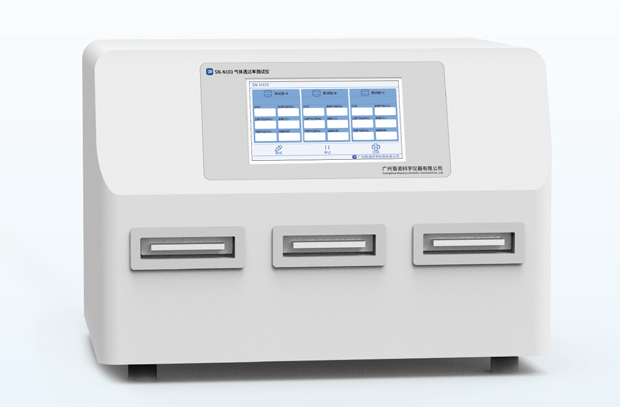

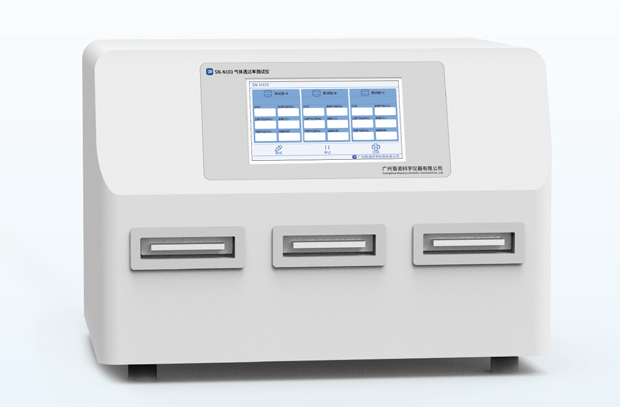

In terms of barrier performance testing, the permeation of gases and water vapor is a key factor affecting drug stability. Our gas transmission rate testers and water vapor transmission rate testers can accurately measure the barrier data of various films, aluminum foils, and composite materials against oxygen, moisture, etc., ensuring that the packaging effectively resists external environmental factors and maintains the quality and stability of the drug throughout its shelf life. These instruments fully comply with authoritative standards such as the Chinese Pharmacopoeia, YBB, ISO, and ASTM.

Pharmaceutical packaging needs to withstand various physical tests during the distribution process. Our electronic tensile testing machine, falling ball impact tester, and bursting strength tester can simulate and evaluate the mechanical properties of materials under tensile, impact, puncture, and compression conditions, thereby screening out packaging materials with sufficient strength and toughness to prevent drug contamination or failure due to packaging damage.

Packaging integrity is a direct barrier to prevent pharmaceutical contamination or spoilage. Sealing testers can efficiently verify the tightness of seals on containers such as bottles, bags, tubes, and cans; while high-precision pinhole detection stations can accurately identify minute defects on the surface of materials such as aluminum foil and PVC that are difficult to detect with the naked eye, eliminating the risk of leakage caused by micropores.

Chemical compatibility is equally important for drug safety. Our gas chromatographs and their accompanying headspace samplers are specifically designed to detect residual solvents or volatile organic compounds in packaging materials, ensuring that the packaging itself does not become a source of contamination and fully meeting the stringent chemical safety requirements for pharmaceuticals.

Furthermore, our heat-sealing equipment can provide optimization and validation solutions for the heat-sealing processes of various film materials, specifically addressing the unique processes involved in pharmaceutical manufacturing and sterilization. Our high-temperature, high-pressure sterilization autoclave can realistically simulate the high-temperature, high-pressure sterilization environment, verifying the resilience of packaging materials. To predict the performance of pharmaceuticals under real storage and transportation conditions, our constant temperature and humidity chamber and simulated transport vibration test chamber can reproduce temperature and humidity changes and road vibrations in the laboratory, providing forward-looking and reliable data for packaging design.

We deeply understand that every testing instrument is linked to the safety of the final product. Therefore, we are committed to fulfilling our promises with a "scientific heart," striving to become a reliable partner for quality control in the pharmaceutical industry through stable, accurate, and compliant equipment. From R&D to production, from raw materials to finished products, we provide not just instruments, but a complete systemic solution dedicated to enhancing drug safety.