In the field of packaging quality inspection, when dealing with films, sheets, paper, and packaging components, a fundamental question is often raised: "Can the oxygen transmission rate (OTR) test be applied to all these different materials?" The answer is: the core testing principle can be unified, but specific applications must precisely match the instrument's design limitations. This article will delve into the essence of oxygen transmission rate (OTR) testing, bringing higher reliability and cost-effectiveness to your testing work.

I. Understanding the core of testing, starting from the essence of materials

The physical basis of all oxygen permeability tests is to measure the rate at which oxygen molecules pass through a material driven by a concentration gradient. For most flexible packaging and planar materials, whether the final form is a roll film, a sheet, or a cut sample, the barrier properties of the material itself are the starting point for evaluation.

-

Thin films and sheets : This is the foundation and core of barrier testing . It assesses the inherent properties of the material itself (such as PE film, aluminum foil composite film, and barrier coated sheets).

-

Specialty paper : Commonly used in high-requirement packaging (such as coffee bags, precision parts packaging). Testing its barrier properties is crucial for evaluating its anti-oxidation and aroma retention effects.

-

Flat Pouch/Sheet : Specifically refers to a flat packaging unit that does not form a three-dimensional container , such as the aluminum foil layer of a tablet blister pack or the cut-out material of a bagged food. The test assesses the performance of the flat material components that make up the packaging .

Key takeaway : For the materials mentioned above, the testing focuses on their barrier properties as homogeneous or composite planar materials . This is precisely the area where the standard coulometric (isobaric) oxygen permeability tester excels and is designed.

II. Implementation of the testing method: Why is the coulomb method the gold standard?

Core method: Coulometric/Equal Pressure Method

-

Principle : The sample divides the test chamber into two sides. High-purity oxygen flows on one side, and a high-purity carrier gas (such as nitrogen) flows on the other. After passing through the sample, the oxygen is carried to the coulometric sensor by the carrier gas . The sensor converts the oxygen molecules into an electrical signal, and the oxygen permeation is accurately calculated using Faraday's law.

-

Why it's the first choice :

-

Extremely high precision and sensitivity : It is particularly good at testing high-barrier materials and extremely low oxygen permeability (down to 0.005 cm³/m²·day·atm level).

-

Excellent repeatability and reproducibility : providing a reliable data comparison basis for R&D and quality control.

-

Extensive international standard compliance : directly corresponds to core standards such as ASTM D3985, ISO 15105-2, and GB/T 19789.

Key instrument features: Optimized for planar material testing

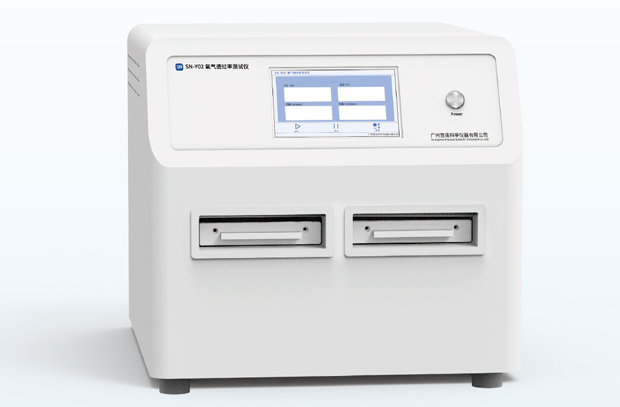

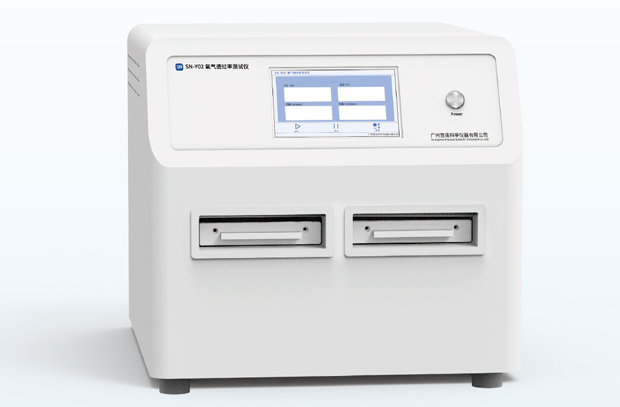

A professional thin-film oxygen permeability testing device is designed with the core principles of ensuring accuracy, convenience, and standardization in testing planar samples.

-

Precision temperature and humidity chamber : Provides a stable testing environment that meets standard requirements (such as 23°C, 50%RH).

-

Intelligent clamping and sealing system : Ensures that film, sheet or paper samples of different thicknesses and hardness are sealed quickly, uniformly and leak-free.

-

Automated testing and data analysis : An integrated software control testing process that automatically calculates and generates reports.

III. Defining Boundaries: Matching Instrument Capabilities with Packaging Form

A key industry consensus is that no instrument is "omnipotent." The value of specialized instruments lies in providing the most reliable data within their design scope.

Selection Insights : Clearly define your primary testing targets . If your core need is to evaluate the barrier properties of raw materials (films, sheets, paper) or flat packaging components , then choosing an instrument like those from Guangzhou Solutia, which specializes in this area, is the best way to achieve the highest cost-effectiveness and optimal data reliability.

IV. How to Choose Your Professional Oxygen Permeability Analyzer? Decision Checklist

When choosing an oxygen permeability tester , please make a rational judgment based on the following list:

-

Is the core technology authoritative?

-

✅ Adhere to the coulomb method principle : This is the cornerstone for obtaining high-precision data, especially in addressing the challenges of high-barrier materials.

-

❌ Be cautious about non-mainstream or outdated detection principles, as they may have shortcomings in terms of data authority.

-

Does the instrument design match my core sample?

-

✅ Choose an instrument that matches your expertise . For example, if you primarily test various films and sheets, Guangzhou Shounuo 's oxygen permeability tester is specifically optimized for this purpose. Its stable performance, standard-compliant testing chamber, and intelligent operation ensure the excellent completion of your core tasks.

-

❌ Be wary of devices that sacrifice core performance or reliability in pursuit of "multi-functionality." A device that cannot provide top-tier stability in its claimed primary function often has questionable additional features.

-

Does this meet and simplify my compliance process?

-

Can you improve the efficiency of my lab?

-

✅ Modern instruments should have functions such as automatic testing, multi-task queuing, electronic data recording, and audit trail to reduce human error and improve management standardization.

V. Guangzhou Shounuo: A Reliable Partner Focusing on Barrier Testing of Planar Materials

Guangzhou Shounuo Scientific Instruments Co., Ltd. adheres to the philosophy of "achieving excellence in professional fields." Our oxygen permeability tester series does not pursue broad form coverage, but rather focuses on the oxygen barrier performance testing of films, sheets, paper, and related flat packaging materials .

VI. Frequently Asked Questions (FAQ)

Q1: Our lab mainly tests PE films and aluminum foil composite films, and occasionally needs to test bottles. Are Guangzhou Solutia's instruments suitable?

A: They are very suitable for your main needs. Guangzhou Solutia instruments are ideal for testing various films and composite sheets, providing top performance in over 90% of your core work. For occasional bottle testing, we recommend a more economical solution: cutting the bottle material into flat specimens for testing, which can assess the material's inherent properties. If you need to test the overall sealing performance of the bottle (including the cap), you need to evaluate the necessity and return on investment of purchasing a dedicated container testing instrument.

Q2: How do you ensure that our test data is accepted by our international clients?

A: Data acceptance is based on three points: standard compliance, instrument calibration status, and operational standardization . Guangzhou Solutia testing instruments fully comply with international standards such as ASTM D3985. We recommend regular verification using the original manufacturer's traceable calibration membrane. Simultaneously, establish standard operating procedures (SOPs). The instrument's audit trail function can completely record the testing process, meeting compliance requirements.

Q3: Our business may expand in the future. Will purchasing only one instrument for testing thin films be insufficient?

A: Specialized equipment is the foundation for building laboratory capabilities. Prioritizing investment in equipment that addresses our most critical and frequent needs is the most efficient strategy. Guangzhou Shounuo's instruments are perfectly suited for your current testing tasks on planar materials, ensuring the quality of core data. If our business expands to testing other types of materials in the future, we can then assess and purchase additional specialized equipment based on specific needs. This phased investment strategy is more prudent and wise.

Conclusion

In the world of packaging inspection, accurately defining needs and matching equipment is more important than pursuing "large and comprehensive" solutions. For oxygen barrier performance testing of films, sheets, paper, and flat packaging, choosing a specialized piece of equipment like the Guangzhou Solutia Oxygen Permeability Tester, which is specifically designed and deeply optimized , means choosing higher data reliability, a better user experience, and clearer cost-effectiveness.

Let us focus on the essence of your material barrier properties and empower precise decision-making with professional instruments.