Industry News

-

Time:28.01.2026This article details the working principle, technical advantages, and application fields of soft package seal integrity testers, covering high-precision detection technologies such as the vacuum decay method. It assists industries like food and pharmaceuticals in achieving rapid, non-destructive testing of packaging seals, enhancing product quality and safety. Explore key selection points and industry trends to provide a professional solution for your packaging quality control.

-

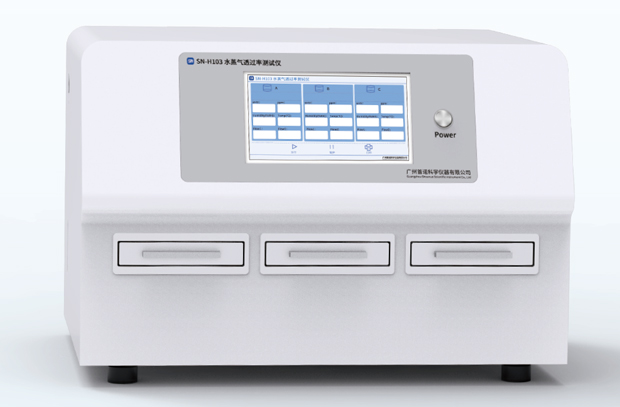

Time:14.01.2026This article recommends high-quality manufacturers of Water Vapor Transmission Rate Testers (WVTR Testers), including Guangzhou Shounuo, MOCON, Jinan Languang, Jinan Sike, and others. It provides a detailed selection guide to help you choose a precise and efficient detection device based on your testing requirements, standard compliance, and service considerations.

-

Time:09.01.2026In the pharmaceutical industry, drug safety and efficacy are the lifeline. This depends not only on the composition and manufacturing process of the drug itself but also on the quality of its external "protective layer"—the pharmaceutical packaging material. Packaging materials come into direct contact with drugs, and their barrier properties, seal integrity, physical strength, and chemical stability directly impact the safety and effectiveness of the drug during storage, transportation, and even use.

-

Time:25.12.2025In the packaging and printing industry, especially in the flexible packaging sector for food and pharmaceuticals that comes into direct contact with products, strict control of solvent residues is the lifeline for ensuring safety and compliance. Accurate detection of the purity and content of dozens of organic solvents, such as benzene, toluene, xylene, and ethyl acetate, has become an indispensable part of the industry chain. Addressing this demand for precision, Guangzhou Shounuo Scientific Instruments Co., Ltd. 's GC-05 gas chromatograph , as an outstanding representative of dedicated testing solutions for the domestic flexible packaging industry, is setting a new testing standard for the industry with its superior performance and high adaptability.

-

Time:19.12.2025For many flexible packaging, food, pharmaceutical, and new materials companies, water vapor transmission rate testers are a critical quality checkpoint for ensuring product shelf life and performance. However, faced with a variety of technologies and models on the market, making an informed choice within a limited budget and avoiding the traps of "low price, low quality" or "redundant functions" is a professional task that requires strategy.

-

Time:17.12.2025In the field of packaging quality inspection, when dealing with films, sheets, paper, and packaging components, a fundamental question is often raised: "Can the oxygen transmission rate (OTR) test be applied to all these different materials?" The answer is: the core testing principle can be unified, but specific applications must precisely match the instrument's design limitations. This article will delve into the essence of oxygen transmission rate (OTR) testing, bringing higher reliability and cost-effectiveness to your testing work.

-

Time:15.12.2025In summary, the Friction Coefficient Tester is a vital bridge connecting the physical properties of packaging materials to their actual performance on production lines. It is integral to quality monitoring across the entire chain—from raw materials to in-process goods and finished products—and is widely used in numerous industries sensitive to packaging performance, such as food, pharmaceuticals, daily chemicals, and logistics.

-

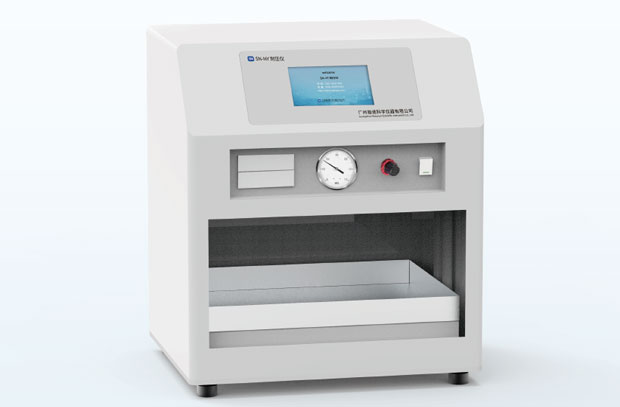

Time:09.12.2025In the modern packaging industry, the counter-pressure autoclave (also known as a counter-pressure sterilization retort or counter-pressure high-temperature sterilizer) is one of the essential pieces of equipment for ensuring product safety and extending shelf life. This article will delve into the core functions, applicable scenarios, working principles, and key considerations for selecting this equipment, providing valuable insights for professionals in the packaging industry.

-

Time:04.12.2025In many fields, including packaging, food, pharmaceuticals, electronics, and new materials, the barrier properties of materials are crucial. Among these, water vapor transmission rate (WVTR) is a key indicator for measuring the moisture barrier ability of films, sheets, and even finished packaging. Choosing an accurate, efficient, and stable water vapor transmission rate tester is decisive for ensuring product quality, optimizing packaging solutions, and meeting regulatory standards. Faced with a diverse range of products on the market, how can customers make an informed choice?

-

Time:02.12.2025Among the many quality indicators of product packaging, pressure resistance is a fundamental and crucial factor determining whether it can safely reach the end consumer. Whether it's a plastic bag carrying goods or a medical infusion bag related to life and health, the static and dynamic pressures it endures during warehousing, stacking, and long-distance transportation directly test the physical limits of the packaging. Packaging bag pressure resistance testers are core testing equipment that quantifies this limit and verifies the reliability of packaging structures, building a solid line of defense for product safety for enterprises.