In the pharmaceutical industry, drug quality and safety are paramount. The performance of packaging materials (pharmaceutical packaging materials) that come into direct contact with drugs directly impacts their stability, effectiveness, and safety. Barrier properties are a key performance indicator for pharmaceutical packaging materials, determining their ability to effectively resist the intrusion of gases like water vapor and oxygen, while preventing the loss of active ingredients.

1. Why is barrier testing so important?

Pharmaceuticals are very sensitive to environmental factors such as light, humidity, and oxygen. If the packaging barrier properties do not meet the standards, it may lead to:

Drugs deteriorate due to moisture: Water vapor intrusion can cause tablets to deliquesce, powders to clump, and biological agents to become inactive.

Drug oxidation failure: Oxygen penetration will accelerate the oxidation reaction of certain active ingredients and reduce drug efficacy.

Component dissipation: Volatile components in the package may also be lost through the packaging material.

Therefore, strict and accurate barrier testing is an essential step to ensure the stable quality of drugs throughout their shelf life.

2. Core barrier properties testing method and corresponding instruments

Currently, there are several key tests for barrier properties testing of pharmaceutical packaging materials:

1. Water vapor barrier test

Test Purpose: To measure the packaging material's ability to block water vapor. This is crucial for blister packaging, aluminum-plastic composite films, and pharmaceutical plastic bottles.

Keyword instrument: water vapor transmission rate tester(WVTR Tester)

Methods and recommendations:

This method is mainly based on infrared sensor method or gravimetric method. The sample is sandwiched between the test chambers, creating a stable humidity difference on both sides. Water vapor permeates from the high humidity side to the low humidity side. The water vapor transmission rate is detected and calculated by a precise sensor.

Solutia Instruments recommends: Solutia Instruments' SN-H series WVTR tester, equipped with imported infrared moisture sensors, offer high test accuracy and good repeatability. They fully comply with multiple pharmaceutical packaging material testing standards, including ASTM F1249, ISO 15106-3, and GB/T 26253, making them an ideal choice for pharmaceutical companies and testing agencies conducting water vapor barrier performance research.

2. Oxygen barrier test

Test purpose: To evaluate the barrier properties of packaging materials to oxygen. This is particularly important for easily oxidized pharmaceuticals (such as vitamins, antibiotics, and biological products).

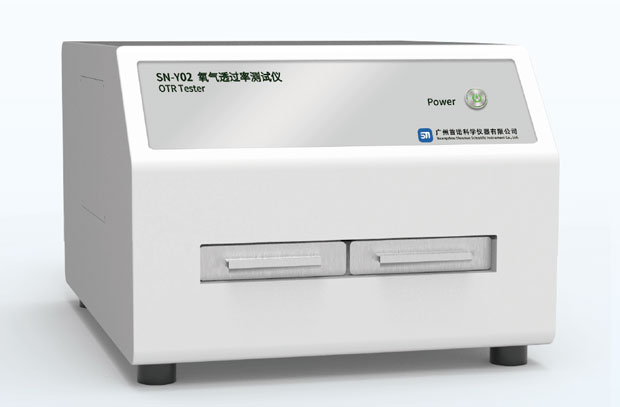

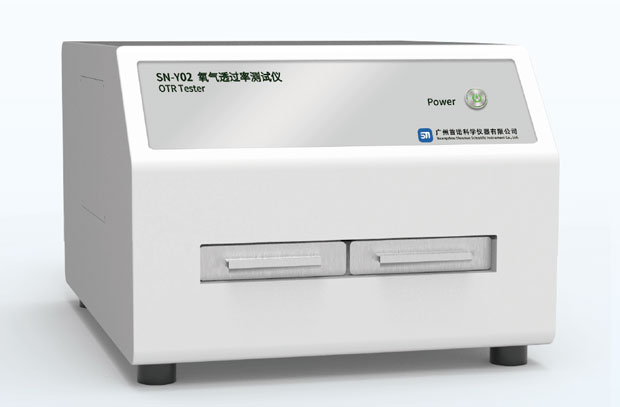

Keyword instrument: oxygen transmission rate tester(OTR Tester)

Methods and recommendations:

Commonly used methods include the isobaric method (coulometric method) and the differential pressure method. The isobaric method uses the power consumption of the oxygen sensor to accurately calculate the transmittance and has extremely high sensitivity.

Solutia Instruments recommends: Solutia Instruments' SN-Y02 OTR Tester is designed for high-precision oxygen transmission rate testing. It can sensitively and accurately detect extremely low oxygen transmission rates of pharmaceutical packaging materials, providing the most reliable "anti-oxidation armor" for your drugs.

3. Comprehensive gas barrier test

Test purpose: In addition to oxygen, it is sometimes necessary to test the barrier properties of materials to other gases such as nitrogen (N₂) and carbon dioxide (CO₂).

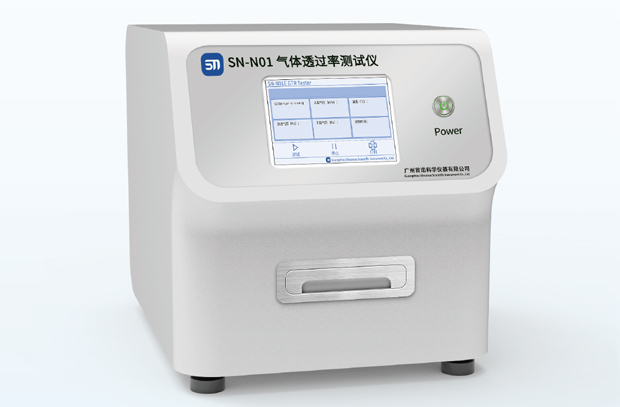

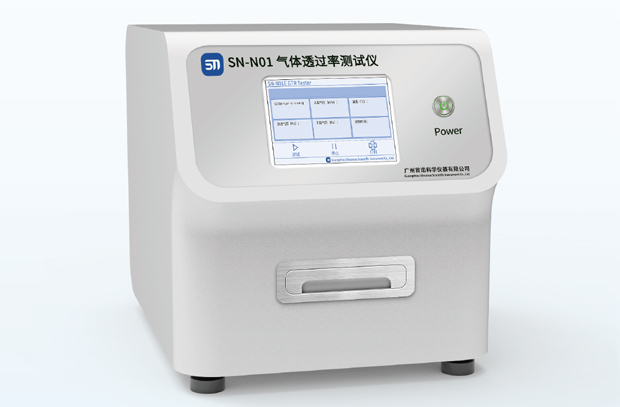

Keyword instrument: Gas Permeability Tester

Methods and recommendations:

The differential pressure method is one of the most widely used methods. It uses the pressure difference between the two sides of the sample to allow gas to permeate from the high-pressure side to the low-pressure side, and calculates the gas permeability by monitoring the pressure change on the low-pressure side.

Solutia Instruments recommends: Solutia Instruments' SN-N series GTR Tester , based on the differential pressure method, are specialized for testing the permeability of various pharmaceutical packaging films and sheets for gases such as O₂, CO₂, and N₂. Their wide measurement range and high accuracy meet comprehensive testing needs for materials ranging from high-barrier to standard barrier materials.

3. Choose a professional testing partner

To do one's job well, one must first sharpen his tools. Selecting a testing instrument that meets standards, offers stable performance, and produces accurate data is the foundation for building a quality control system for pharmaceutical packaging materials.

Guangzhou Solutia Scientific Instrument Co., Ltd. , a high-tech enterprise specializing in packaging testing, focuses on providing customers with precise and reliable testing solutions based on the core concept of "Science." The water vapor transmission rate tester , oxygen transmission rate tester , and gas transmission rate tester recommended above are Solutia's star products in the pharmaceutical packaging testing field. They can fully assist pharmaceutical companies, packaging material manufacturers, and third-party testing agencies in strictly controlling quality.

Conclusion

Drug safety is no small matter. Strictly monitoring the barrier properties of pharmaceutical packaging materials through scientific testing methods and sophisticated instrumentation is essential to ensuring drug safety and protecting public health. Embrace precision testing and provide reliable "protective clothing" for every tablet and every dose.

To learn more about Solutia Instruments' WVTR Tester , OTR Tester and other products, please feel free to contact us for professional product information and solutions.