In the field of packaging testing instruments, ensuring the gas barrier properties of packaging materials is a key aspect of quality control. Among these, gas permeability testers and oxygen permeability meters are two crucial and frequently mentioned pieces of equipment. Many users, especially those new to the field, easily confuse the two. This article will delve into the core differences between gas permeability testers and oxygen permeability meters, providing you with a clear selection guide to help you choose the most suitable packaging barrier testing instrument for your laboratory .

Essential difference: The test object and the accuracy requirements are different.

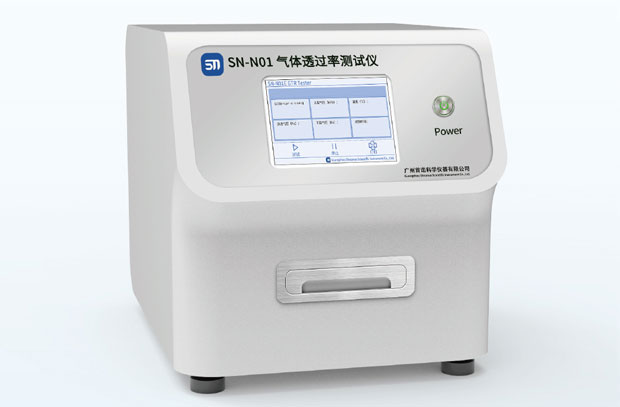

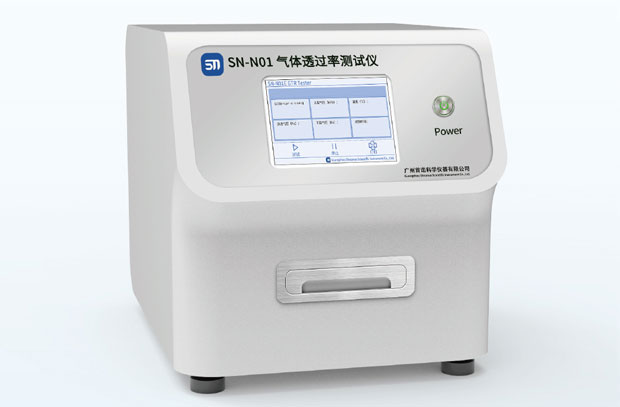

Fundamentally, the core difference between an air permeability tester and an oxygen permeability meter lies in the types of gases they test and their testing accuracy. An air permeability tester is a relatively broad concept, primarily focusing on measuring the overall barrier performance of packaging materials to air and similar gas mixtures. In industry standards, it is often referred to as an air permeability tester , and its test results are typically expressed as the volume of gas passing through a unit area of material per unit time under a certain pressure difference. These instruments are widely used in evaluating the air permeability of textiles, non-woven fabrics, leather, paper, and some general-purpose plastic films.

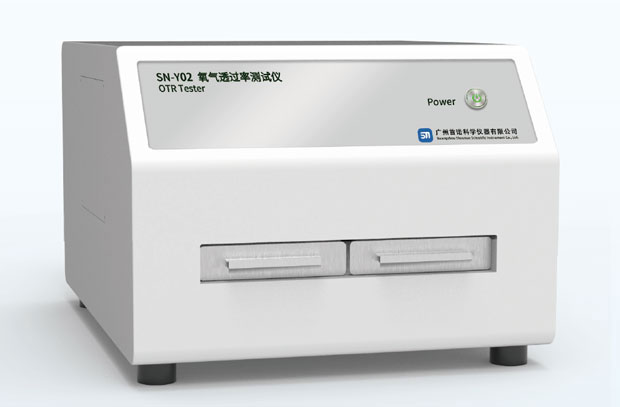

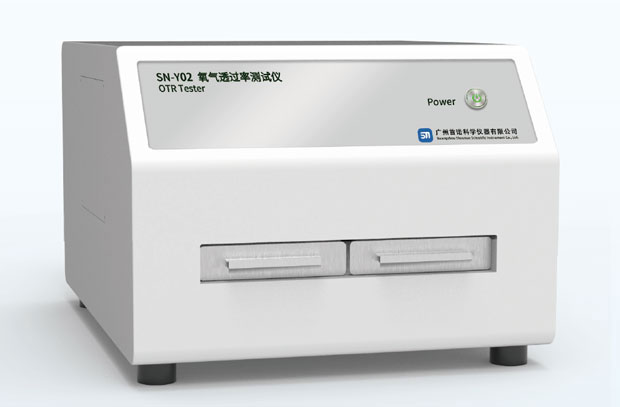

An oxygen permeability meter, or more accurately, an "oxygen transmission rate tester," is a highly specialized instrument for testing air permeability . It doesn't test mixed gases; instead, it precisely measures the ability of packaging materials to block single, specific oxygen molecules . Since oxygen is a major factor leading to food oxidation and spoilage, and reduced efficacy of pharmaceuticals, oxygen permeability meters are indispensable equipment in industries with extremely high shelf-life requirements, such as food, pharmaceuticals, and medical devices. The accuracy of its test results is even higher, typically expressed as the amount of oxygen permeating through a unit area of material per unit time.

In short, all oxygen permeability meters can be considered a type of specialized air permeability tester, but not all air permeability testers can perform high-precision oxygen permeability tests. If you need to assess the overall performance of a material in terms of airflow, such as determining the windproofness of a windbreaker fabric or the airtightness of a regular bag, an air permeability meter is a suitable choice. However, if your product is extremely sensitive to oxygen, such as premium potato chip, milk powder, coffee, or pharmaceutical blister packaging, then an oxygen permeability meter specifically designed to measure oxygen barrier properties is a crucial piece of equipment you must have.

How to scientifically select instruments: Clarify needs and examine instrument performance.

Faced with a dazzling array of packaging barrier testing instruments on the market , a scientific purchasing decision should be based on a clear understanding of one's own needs and the performance specifications of the instrument itself.

The first step is to define your testing objectives. What material do you need to test? Is it a film, sheet, or a complete package such as a bottle or bag? Which gas is your final product most sensitive to? If the answer is oxygen, then a dedicated oxygen permeability meter is indispensable. If your needs lean more towards a basic screening of overall barrier properties against gases such as air, nitrogen, or carbon dioxide, then a general-purpose permeability tester may be more cost-effective.

After determining the instrument type, evaluating its performance is crucial. Key indicators include testing range (the maximum and minimum transmittance the instrument can measure), testing accuracy, and repeatability. High-precision instruments provide reliable data, offering a solid basis for your R&D and quality control. Ease of operation is also an important factor. Modern advanced permeability testing instruments are typically equipped with intelligent operating systems, significantly reducing human error and improving testing efficiency. Furthermore, whether the instrument complies with relevant international, national, or industry standards (such as ISO, ASTM, GB/T, etc.) is fundamental to ensuring the authority and comparability of the data and must be confirmed during the purchase process.

Finally, consider your long-term needs and the supplier's service. A high-quality packaging barrier testing instrument is a laboratory's long-term asset. Choosing a technically strong supplier that can provide comprehensive installation, training, calibration, and after-sales service is far more important than simply focusing on the initial purchase price. An excellent supplier can not only provide equipment that meets your current needs but also become a reliable partner for your future technology upgrades and expansion of testing capabilities.

Summarize

In summary, while air permeability testers and oxygen permeability meters both fall under the category of barrier testing, their application areas and accuracy requirements differ significantly. Understanding these differences is the first step in making the right purchasing decision. As website operators, we deeply understand the value of a reliable and accurate testing device in ensuring product quality and enhancing brand reputation. We hope this article will help you clearly define your needs and find the most suitable and trustworthy packaging barrier testing instrument for your laboratory, safeguarding the quality of your products.