Abstract: Barrier properties are crucial in packaging, food, pharmaceuticals, electronics, and advanced materials. Water vapor transmission rate ( WVTR ) testers (often called moisture permeation meters ) are key instruments for measuring a material's moisture resistance. Many companies are confused when choosing between the two dominant methods: the cupping method and the infrared method. This article will delve into the principles, advantages, and disadvantages of these two technologies to help you make the most informed investment decision.

Keywords: Water Vapor Transmission Rate Tester, Moisture Permeability Tester, Cupping Moisture Permeability Tester, Infrared Moisture Permeability Tester, WVTR Test, Package Barrier Tester

1. Core indicators: What is water vapor transmission rate (WVTR)?

Water Vapor Transmission Rate (WVTR) refers to the rate at which water vapor passes through a material per unit area per unit time under specific temperature and humidity conditions. It is a key indicator for evaluating the moisture-proof and fresh-keeping capabilities of materials such as films, sheets, and packaging bags. Lower WVTR values indicate better moisture resistance.

Selecting an accurate, efficient, and standard-compliant water vapor transmission rate tester is the first step to ensuring product quality control and R&D data accuracy.

2. Technology Showdown: Cup Method vs. Infrared Method

At present, the mainstream detection technologies of water vapor permeability testers are divided into two camps: weight method (cup method) and sensor method (infrared method) .

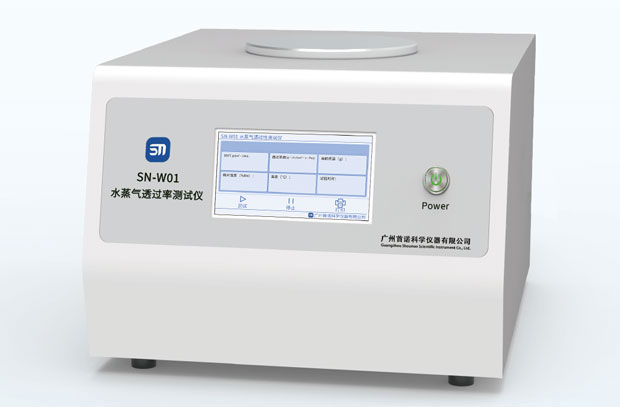

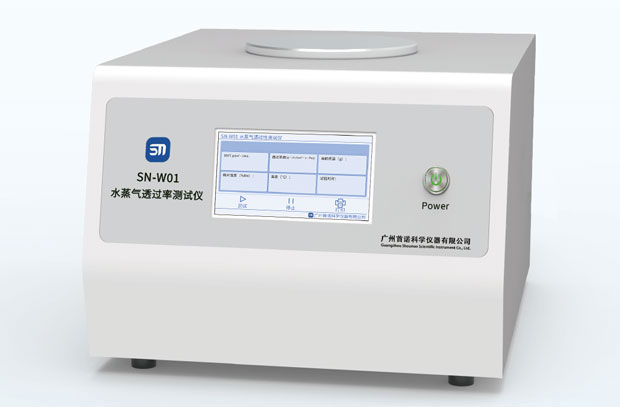

1. Cupping Vapor Permeability Tester: A Classic and Reliable "Benchmark Method"

2. Infrared Vapor Permeability Tester: Efficient and Accurate "Modern Technology"

-

Working Principle: Utilizing the infrared sensor's ability to specifically detect water vapor concentration, the sample is clamped in the center of a test chamber, with a constant-humidity nitrogen atmosphere on one side and dry nitrogen on the other. After water vapor permeates the sample, it is carried by the flowing dry nitrogen to the infrared sensor for precise detection, directly calculating the WVTR value.

-

Core advantages:

-

The test speed is extremely fast: the test can usually be completed in a few minutes to an hour, which greatly improves the efficiency of quality inspection and R&D.

-

High precision and good repeatability: Fully automatic detection avoids human errors and the results are accurate and reliable.

-

Rich data: It can display the permeation curve in real time and provide more parameters such as permeability, solubility coefficient, diffusion coefficient, etc.

-

Meet high-end standards: Meets ASTM F1249, ISO 15106-2 and other test standards for high-barrier materials.

-

Potential limitations:

-

High equipment investment: The core infrared sensor technology leads to relatively high equipment costs.

-

Test range limitation: For materials with extremely high moisture permeability, dilution gas may be required, which makes the operation slightly more complicated.

3. Decision Guide: How to choose a moisture permeability meter based on business needs?

The choice of water vapor transmission rate tester technology should be based on your specific application scenario, budget and efficiency requirements.

The cupping method vapor permeability tester is preferred if:

-

Limited budget and pursuit of standard compliance: Your laboratory needs to strictly follow standard methods such as GB/T 1037, and the initial investment budget is limited.

-

The test materials are diverse but the frequency is not high: the test materials are diverse but the timeliness of a single test is not critical.

-

As basic teaching or basic research: In colleges and universities or scientific research institutions, it is necessary to show students the most basic testing principles.

Infrared moisture permeability tester is preferred if:

-

Pursuing efficiency and automation: Your production line quality control (QC) or product research and development (R&D) requires fast and large-scale data acquisition.

-

Testing high barrier materials: Mainly testing materials with extremely high barrier properties such as aluminum foil composite films, EVOH high barrier films, solar backsheets, and lithium battery separators.

-

High precision and rich data are required: The repeatability and reproducibility of test results are extremely high, and it is hoped that deeper material penetration parameters can be obtained to guide research and development.

-

Future-oriented and high-end certification: We hope that laboratory equipment will be in line with international standards and meet more stringent industry certification requirements.

IV. Summary

The relationship between the cup method and infrared method water vapor transmission rate tester is not a simple "one replaces the other" relationship, but rather solutions for different application levels.

-

The cup method is the cornerstone, classic and universal.

-

Infrared method is a powerful tool, efficient and accurate.

As a business decision-maker, your choice should be driven by the essence of your business: testing needs, efficiency requirements, and investment budget. A clear understanding of the technical features of the two moisture permeability testers will help you select the most suitable equipment for your development, ensuring product quality and gaining an advantage in market competition.